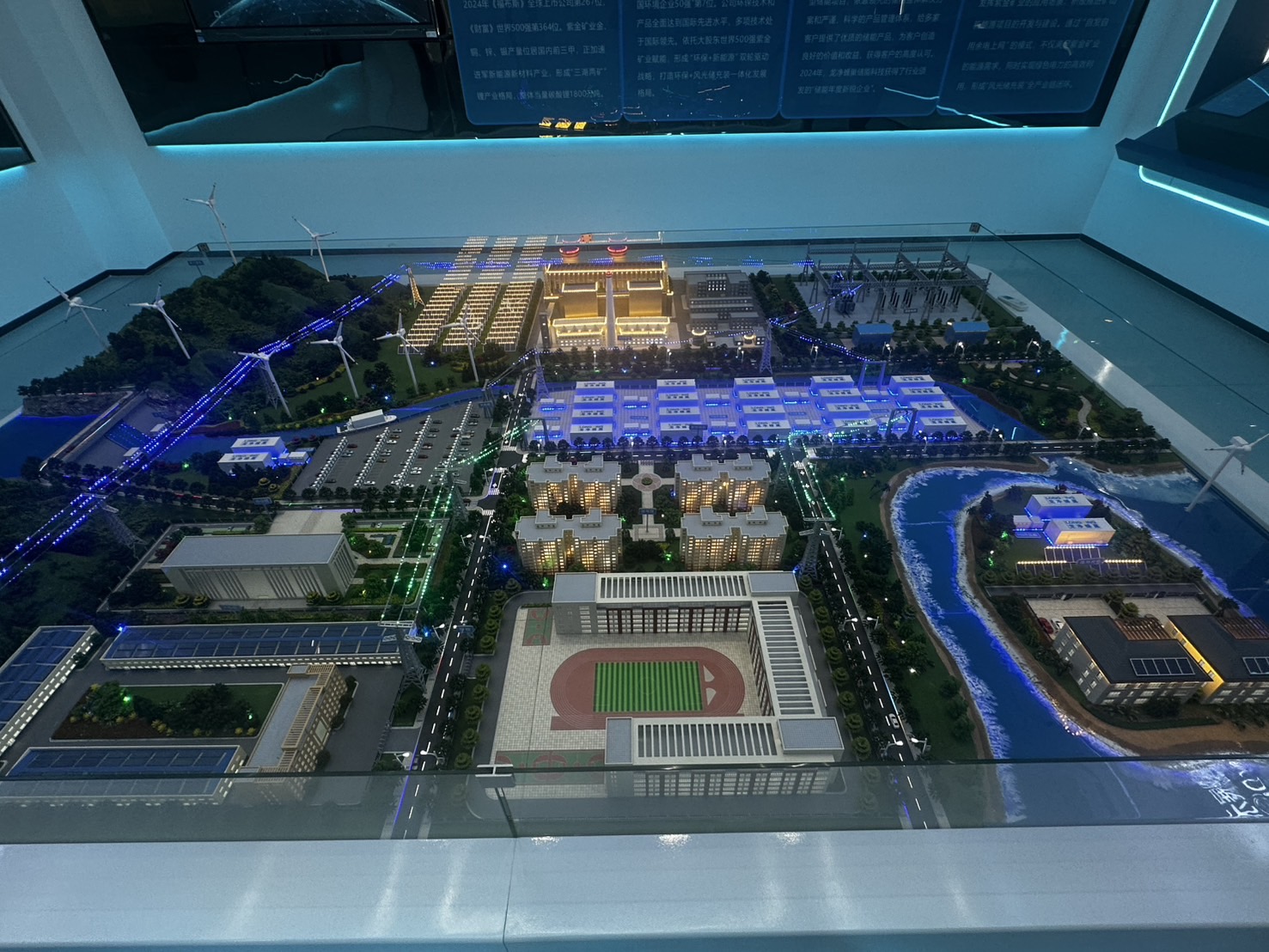

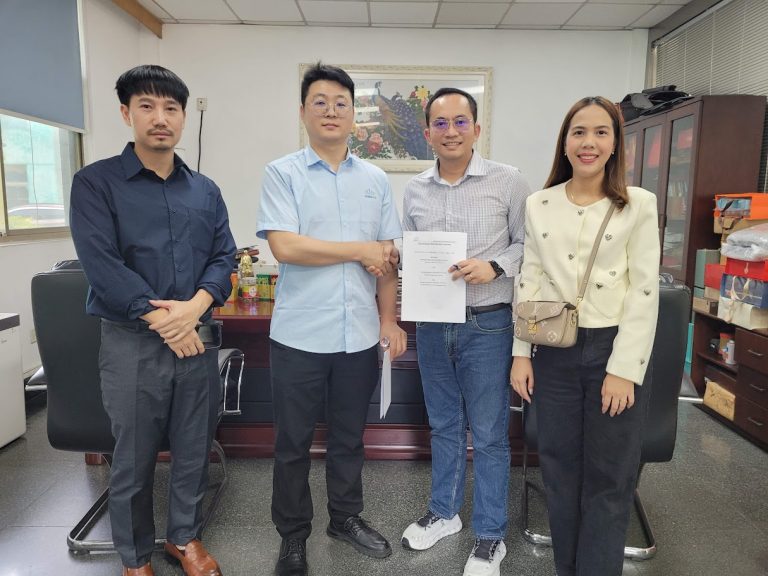

From our recent visit to Longking’s manufacturing and R&D facility in Longyan, Fujian Province, China, we gained unique insight into the company’s advanced capabilities in both electrostatic precipitator (ESP) technology and battery energy storage systems (BESS). Longking was founded in 1971 and today stands as a leading player in environmental equipment and new energy systems.

Technology Spotlight: ESP (Electrostatic Precipitators)

Longking has over four decades of experience in designing and manufacturing ESP solutions for dust removal and ultra-low emission applications.

Key features include:

– High field-intensity electric discharge designs for effective particulate removal.

– Low-temperature wet and dry ESP variants to deal with challenging flue gas conditions.

– Maintenance-friendly, robust systems designed for large‐scale industrial use.

During our visit, we observed the factory’s assembly lines, quality testing of ESP units, and Longking’s in-house R&D of electrode configurations. This visit gave our team firsthand exposure to how Longking controls emission criteria, improves reliability, and implements smart monitoring for long-term equipment performance.

Technology Spotlight: BESS (Battery Energy Storage Systems)

Longking is not only a leader in environmental control, but is also rapidly expanding into the new energy sector—specifically energy storage.

Highlights include:

The company’s integrated approach: from energy storage cell & module production to system integration for grid, industrial and generation-side applications.

Joint ventures and production lines aimed at intelligent, automated battery system manufacturing.

Strategic alignment with clean energy trends: wind/solar storage, industrial park solutions, green power generation.

From our visit, we were able to tour the BESS module workshop, view system integration mock-ups and meet Longking engineers who work on control systems, battery pack design, and grid interfacing. This knowledge will be invaluable as we evaluate future partnerships or system procurements.

Our Visit: Why It Matters

Direct technology evaluation: Seeing equipment, factory processes and engineering talent in person allowed us to validate Longking’s claims and quality standards.

Strategic insights: By engaging with Longking’s team, we gained clarity on how the ESP business and energy storage business align with global decarbonisation, emissions control and grid-modernisation trends.

Opportunity exploration: This visit opens up potential collaboration avenues — whether sourcing ESP units for our projects or exploring BESS solutions for future energy-storage applications.

Why For Our Company & Industry

Given our business focus in air-pollution control systems and energy solutions, integrating technologies like those offered by Longking brings several advantages:

Enabling equipment that meets ultra-low emission targets (important for future regulatory compliance).

Accessing energy-storage systems that support renewables, grid flexibility and industrial energy management.

Gaining supply-chain diversification by working with an experienced manufacturer who straddles both environmental and energy-storage domains.

Conclusion

Our visit to Longking in China was highly productive and insightful. The company’s dual expertise in high-performance ESP technology and rapidly advancing energy-storage systems positions it as a forward-looking partner. We return with renewed confidence that leveraging these technologies will strengthen our capability to deliver advanced solutions — for clean emissions management and next-generation energy systems alike.